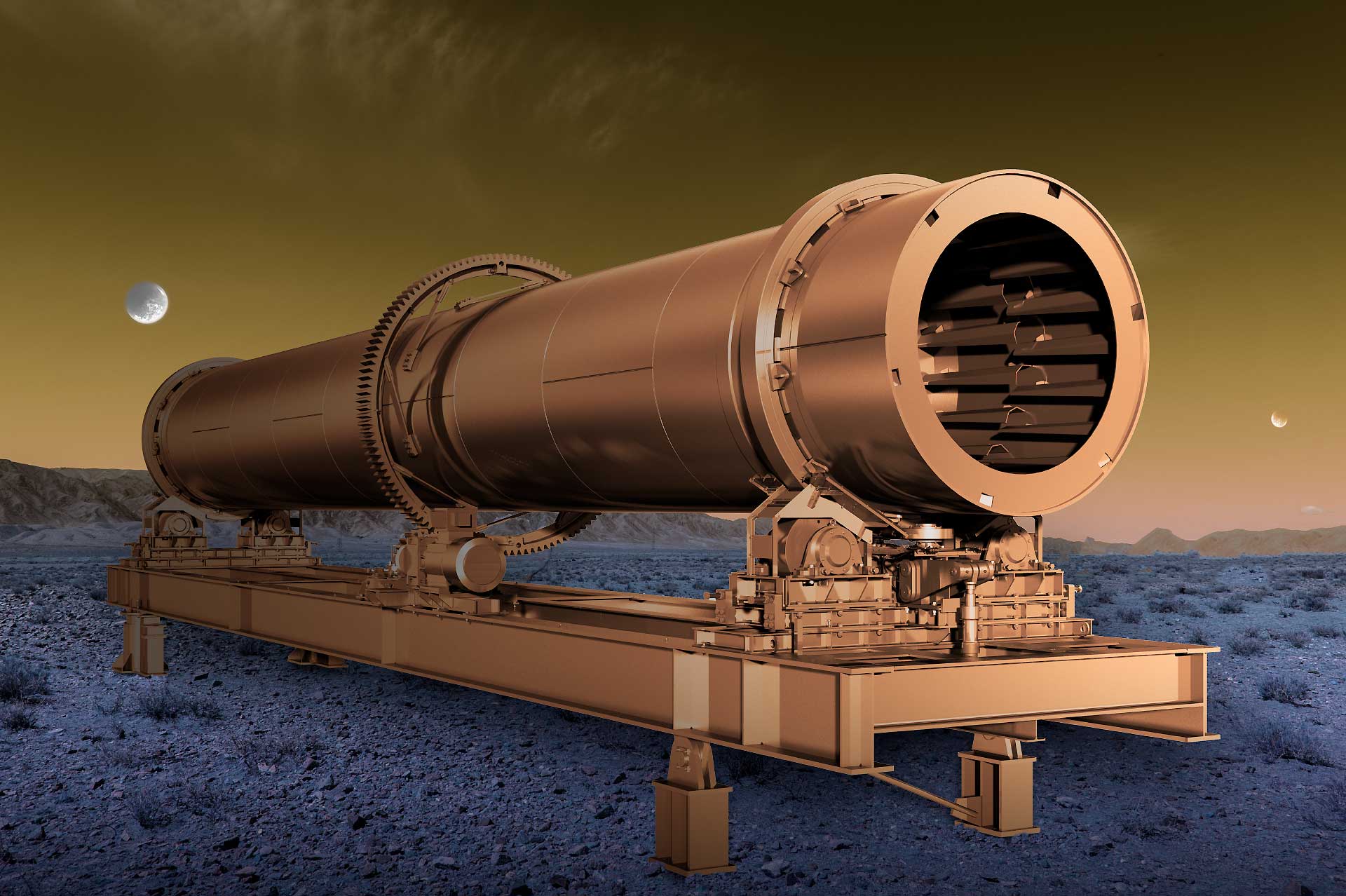

Rotary Dryers

We deliver equipment and components worldwide.

On July 1st, 2024, Zettl GmbH from Munich will take over technology and employees of ZADCON GmbH. The long -term tradition at the Dessau location is continued and specifically expanded. The rotary tube technology is an optimal addition to Zettl product portfolio in the area of drying technology and thermal process engineering.

ZADCON was founded as an engineering office in January 2000 by former design engineers of the HWZ GmbH. HWZ, a subsidiary of the Cologne-based HUMBOLDT WEDAG, was formed from the ZAB Company in Dessau, which in turn was formed from the Company Polysius. Machines and equipment for the cement industry and mineralogical industry have been built in Dessau for neraly 100 years. The employees at ZADCON GmbH thus have have been trained in this traditional environment and have acquired all their expertise here.

More informations about ZETTL.

Dessau is the origin of cement plant manufacturing. More than 150 years ago Gottfried Polysius founded his company in this town, and since 1888 they have been building and selling efficient mills for the cement industry. In 1907 the first complete cement plant was shipped to Egypt, followed by another plant sent to China only one year later. After World War II Polysius had his company expropriated and Zementanlagenbau Dessau (ZAB) took his place. For several decades, until the collapse of the GDR, ZAB shipped over 350 cement plants to destinations worldwide. In 1990 the company became a subsidiary of the Cologne-based HUMBOLDT WEDAG. From there former head of construction, Dipl.-Ing. Karlheinz Schäfer, and a group of experienced design engineers and process engineers founded the ZADCON GmbH in 2000.

The employees of ZADCON have have been trained in this traditional environment and have acquired all their expertise here.

Using these skills, we offer reliable services, that fit the needs of our customers. Our services include i.a. development, construction, implementing and distribution of machines and facilities for construction trade and the chemical, mineralogical and binders industry.

We offer customized solutions for special requests of our customers. Furthermore we construct spare parts for existing facilities, ship them, and optimize them on request. Our employees have decades of technical expertise in engineering at their disposal.

Your contacts:

Secretariat:

Cornelia Schulz

+49 89 81809 80

cornelia.schulz@zettl-munich.de

Branch Manager:

Sipan Khalil

+49 89 81809 81

sipan.khalil@zettl-munich.de

Service / Assemblies:

Tony Redlich

+49 89 81809 86

tony.redlich@zettl-munich.de

مدير الموقع في مدينة ديساو

خدمة العملاء

المهندس سيبان خليل

+49 89 81809 81

sipan.khalil@zettl-munich.de

YOUR BENEFITS

Solid German engineering in the field of system engineering along with quality, customized solutions and punctuality.

Constructive solutions fit to your personal needs, even for unusual problems and niche products.

Because of our cooperation with famous universities, research centers and special laboratories we offer state of the art technology and future-oriented solutions.

We also use reliable existing networks to implement large-scale projects.

Rotary kilns designed and manufactured by us are used for the thermal treatment of various bulk solids.

Tube coolers are mainly used to cool free flowing and fine-grained bulk solids. Tube coolers* can be considered a kind of indirect flash cooler, for the coolant does not come into contact with the bulk material.

Flash coolers are a kind of direct rotary cooler, and are mainly used to cool free flowing and fine-grained bulk solids, but also to cool agricultural products like beet or sugar beet cuttings, dry leaves, soilage, pressed pulps and grain.

Sectional coolers are used to cool fine-grained or coarse-grained bulk solids. The heat is extracted when the bulk solids come into contact with cool sectional surfaces*. Sectional coolers can be considered a kind of indirect drum cooler.

Pyrolysis takes places in an evacuated environment. Pyrolysis kilns are often used for waste pyrolysis, and other processes involving pyrolysis.

Dryers made by ZADCON are both used to dry easy-to-dry materials (sand, gravel, waste glass) and hard-to-dry materials (e.g. clay).

Tube mills are mainly installed in the form of ball tube mills, meaning they utilize ball charges. In some cases rods may be used for milling.

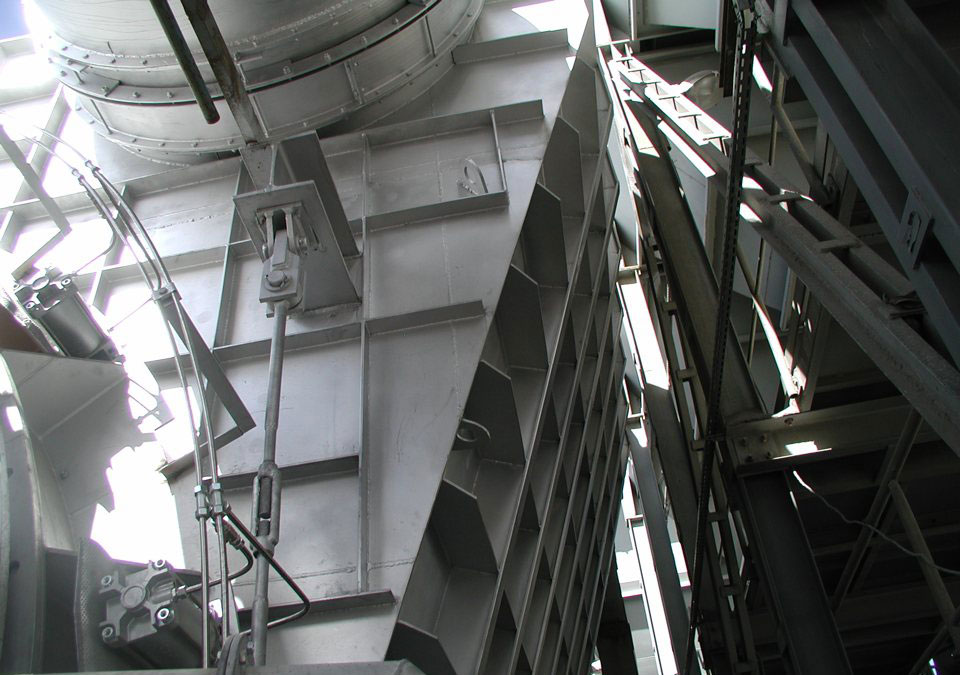

Longitudinal kiln displacements are used for the axial displacement of rotary kilns, dryers and drums for a uniform load and wear of the surfaces of the girth gear/pinion or of the tyres and carrying rollers.

Separators are used for sizing i.e. separating fine-grained builk solids into grain-size categories. This is often needed in connection with crushing units, or with special tasks like producing bulk solids for distributing dust.

In this context, it means sealing a rotating tube towards a fixed inlet or outlet. ZADCON offers different kinds of sealing, each optimized for the conditions it will be used under.

Parts for machines and plants related to the above mentioned main units.

We ship spare parts for plants produced by ZAB Dessau.

Our competitive edge comes from our employees. That is why we are always looking for both experienced professionals and graduates. We want people who always aim for outstanding results, who think analytically and who work well in a team. We work in a constantly changing environment, with new challenges every day and we need people who can grow with these challenges. Unsolicited applications are always welcome.

We are looking for trainees for our team. They assist our employees in analysing, drafting and executing their projects. After gaining some experience, they get to lead small projects of their own for some of our departments. They will gain broad knowledge about the manufacturing of plants and machines, and they will be able to apply the things they learned at college in a practical environment.