Our Scope of Work

Take advantage of our know-how and use our posibilities!

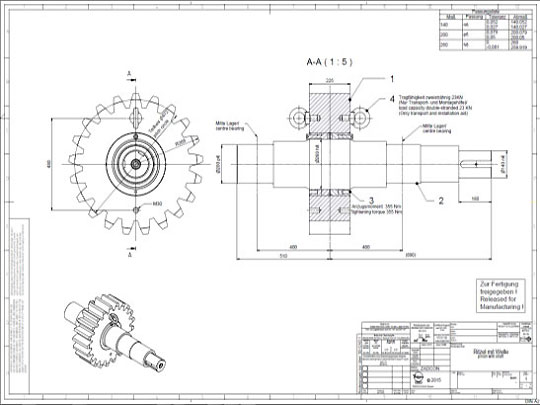

machines, drafts, foundation drawing, assembly drawing, documentation

Procedural design / dimensioning

Rotary Kilns

direct: cement, lime, gypsum, gypsum sulfuric acid, clay, expanded clay, refractories, phosphate, zinc oxide, titanium oxide, aluminium oxide, aluminium hydroxide, siderite, kaolin-bauxite-compounds, aluminium calcination, recycling of zinc, recycling of asbestos concrete, clearing sludge, oil sludge, hazardous waste, activated carbon,

indirect: hydrofluoric acid, petrol coke

Pyrolysis Kilns

waste, torrefaction of biomass, scrap tyres, activated carbon, charcoal, miscellaneous

Rotary Dryers for Bulk Solids

direct current or counter current method

Direct Drying

rotary dryers with different built-in components bucket components, arch components, segment* components

Indirect Drying

Material and hot gas are seperated.

Indirect Drying

steam dryer

Coolers

direct cooling, rotary cooler with different built-in components, indirect cooling using air or water in tube coolers or sectional coolers

Heat Exchangers / Preheaters

cyclone preheaters (multi-stage), shaft preheaters, flash dryers with or without impact reduction

Chambers for Sedimentation of Dust

Post-combustion Chambers

Separators

ZUS (ZADCON separator using recirculating air),

ZHZS (ZADCON high performance centrifugal separator)

Mills

preparation/cement

Components

Furnace Shells

carbon steel, stainless steel, refractory lining

Tyres

loose, welded, screwed, toothed, forged or cast bandages

Sprockets

casting or steel constructions, bridgemountings, connections with clamps, pinions and shafts, bearings, sprocket protection, heat protection, base frames

Drives

main drives, main engines, base frames, heat protection, auxiliary drives, overrunning clutches, auxiliary engines, chain drives, friction wheel drives

Rollers

with shrunked shafts, cast or forged, with rolling bearings, with anti-friction bearings, as a single bearing, as double bearing, base frames, heat protection

Pressure Trestle

stationary, single pressure trestle two rolls, longitudinal kiln guidance, Zwolf (parallelogram), electric, hydraulic, HDR, hydraulic unit, control unit box, base frame

Kiln Outlet Sections

plain, cooling section, disc outlet section, plain, for cooling section, with concrete attachment, outlet cooling section

Kiln Sealings

spring plate sealing, pneumatic sealing, pull-rope sealing

Kiln Inlets and Outlets

cavities, air cooled, water cooled, plain, lined, chutes, plain, water cooled

Casings

inlet casings, outlet casings, temporary casings

Tubes

for gas inside plants

Brick Holding Rings

compensators, hot gas valves

CONSTRUCTION

Our experienced designers use CAD workstations and modern software to work on a broad range of problems like designing machines or different components, optimizing spare parts or different fields of research and development.

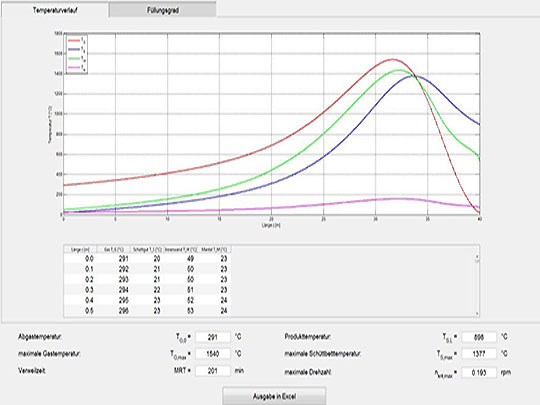

PROCEDURAL DESIGN

At ZADCON, our own experts work at procedural dimensioning of rotary machines and their accessories. Furthermore we work closely with the Institute of Fluid Mechanics and Thermodynamics of the Otto von Guericke Universität in Magdeburg, and with Prof.Dr.-Ing. Specht and Jprof.Dr.-Ing. Herz in particular, and a number of other universities, colleges, research facilities and specialized companies.

CONTRACT MANUFACTURE

ZADCON is not bound to any particular manufacturers, even though we work closely with several excellent partners, some of them near our headquarters. Because of our way of working, we have both: quality and short distances. Production control and inspection is being handled by our specialist engineers.

ASSEMBLY

Our products are shipped worldwide and assembled locally by specialist installation companies.

SUPPORT

Our support writes expertises for existing plants, replaces broken or wear parts and optimizes facilities. They also work at assembling our machines, and offer advice on questions concerning process engineering. Furthermore they are active around the world to support operators of plants, that have been built by ZAB Dessau.

SHIPMENT OF SPARE PARTS

We ship spare parts and constructional components for mechanical and systems engineering around the world. Spare parts include pinions, bearings, shafts, tyres, carrying rollers, girth gears and many more.